Many types of LED lights are suitable for commercial use, including:

- Bay lighting fixtures – high bays and low bays

- Panels and troffers

- Security lighting fixtures

- Accent and task lighting fixtures

- Exterior lighting – parking lot lights and streetlights

LED technology has been adapted for every commercial lighting application imaginable – and new ones are on the horizon.

Five Types of LED Lighting Suitable for Commercial Use

LED’s versatility and energy efficiency gives it the advantage in many commercial uses. Notable examples include:

- Bay lights (high and low) – Bay fixtures are a universally effective option for general commercial lighting purposes. They can be used in department stores, grocery stores, malls, warehouses, airports, indoor amusement centers and any other large interior spaces.

Bay lights are available in several fixture designs. The most important distinction is high bay vs. low bay LED fixtures. High bay LEDs are installed in interiors with a ceiling height between 20 and 40 feet, while low bays are appropriate for ceilings between 12 and 20 feet high. Each option has output characteristics ideal for their intended setting.

LED bay lights are also available in linear or UFO (circular) designs, which describe their shape and distribution patterns. Linear bays are better for illuminating aisles and corridors, while UFOs throw illumination in all directions.

- LED panels and troffers – In office settings, LED lighting is now the norm and has replaced fluorescent technology in most areas.

There are several types of LED office lights, including LED panels, troffers and tubes. LED panels are edge-to-edge lights designed to fit in drop ceilings. They are ideal for general visibility purposes.

LED troffers are also designed for drop ceilings but are slightly recessed up into the ceiling to isolate the light it casts into smaller pools. This makes sense when illuminating individual workstations and also prevents glare from bothering others in the room.

LED tubes are a direct replacement for the fluorescent tubes offices have relied on for decades. LED tubes, available in T4, T8 and T12 designs, are much more energy efficient than fluorescent tubes, and they perform better as well.

- Security lighting fixtures – LED lighting is also incorporated into various types of security fixtures, most of them intended for exterior uses.

LED wall pack lighting and flood lights are the fixtures of choice for commercial use. LED wall packs can be installed directly to building facades and other exterior surfaces. They are also useful for illuminating walkways and areas around buildings and can be tied to occupancy sensors to detect and power on when someone is nearby. High-output LED flood lights can also be tied to occupancy controls in this way.

- Accent and task lighting fixtures – LED lighting can also be built into many types of accent and task fixtures. They include LED strip and cover fixtures, which are compact designs that can fit into tight spaces while still delivering high quality illumination.

Task lights are used to facilitate certain processes or desired behaviors in a commercial setting. For example, LED task lighting may be installed around checkout stations to help customers identify them from a distance, helping push the sales process along.

Accent lighting is designed to bring attention to something else, such as a product display. You will find LED accent lighting in and around product shelving in boutique and luxury commercial settings. Here, accent lights add a layer of sophistication and aesthetics that can help sway purchasing decisions.

- Exterior lighting – LED lighting technology is also a frontline choice for various exterior commercial uses, including parking lot lighting and street lighting. LED lighting’s durability, energy efficiency and extended lifespan elevate it over outdated lighting alternatives, such as high-pressure sodium fixtures and metal halides.

LED parking lot fixtures and streetlights are manufactured in several illumination distribution patterns. Some throw light forward while others create a pool of illumination around the fixture. Again, LED’s versatility here means it can fit on any property, no matter its size or shape.

Four Reasons LED Lighting is Suitable for Commercial Use

The LED lighting revolution has progressed to the point that more than half of all commercial buildings rely on LEDs for their lighting needs. The benefits that have been driving this transition in the lighting industry include:

- Energy efficiency – LED lighting has a significant energy efficiency advantage over metal halides, fluorescents, halogens and other older types of lighting. This advantage is expressed on two levels. One, LED lamps are individually more energy efficient because they are manufactured with semiconductor technology – a major step over heated metal filaments and pressurized gas. Two, LED lighting systems are more energy efficient because less illumination is wasted as the lights can be effectively aimed. Directionality is an advantage that is unique to LED lighting.

- Longevity – LED lighting lasts much longer than all other types of commercial lighting. Halogens provide 1,000-2,000 hours before replacement is recommended. Metal halides last around 10,000 hours. Fluorescent lights are the longest lasting among older types of lighting with 20,000 hours being a typical lifespan.

On the other hand, the typical LED light will provide at least 50,000 hours of quality illumination.

- Performance – LED lights can output extremely bright light that is more uniform than other lighting options. LED light also renders color much better than other types of commercial lighting, which improves long-distance visibility and improves safety, as a result.

- Controllability – LED fixtures are compatible with all modern lighting controls, such as timers, dimmers, photocells and occupancy sensors. These controls can enhance an LED lighting system’s energy efficiency further by ensuring lights are only powered on when they are needed. Advanced lighting controls are also recommended for security applications, and LED’s compatibility allows for a greater range of security focused uses.

A Lighting Expert Can Help Determine the Best LED Lights for Commercial Use

LED lighting manufacturers have rapidly developed high quality LED lights for nearly every application and setting imaginable, so there is likely an LED lighting solution for your project as well. The challenge is determining which fixtures to incorporate into your project.

This is where a commercial lighting expert can provide considerable value. With an expanded selection of commercial fixtures and specialized tools – like photometric software – lighting professionals can identify the most effective and cost-efficient lighting system for any property.

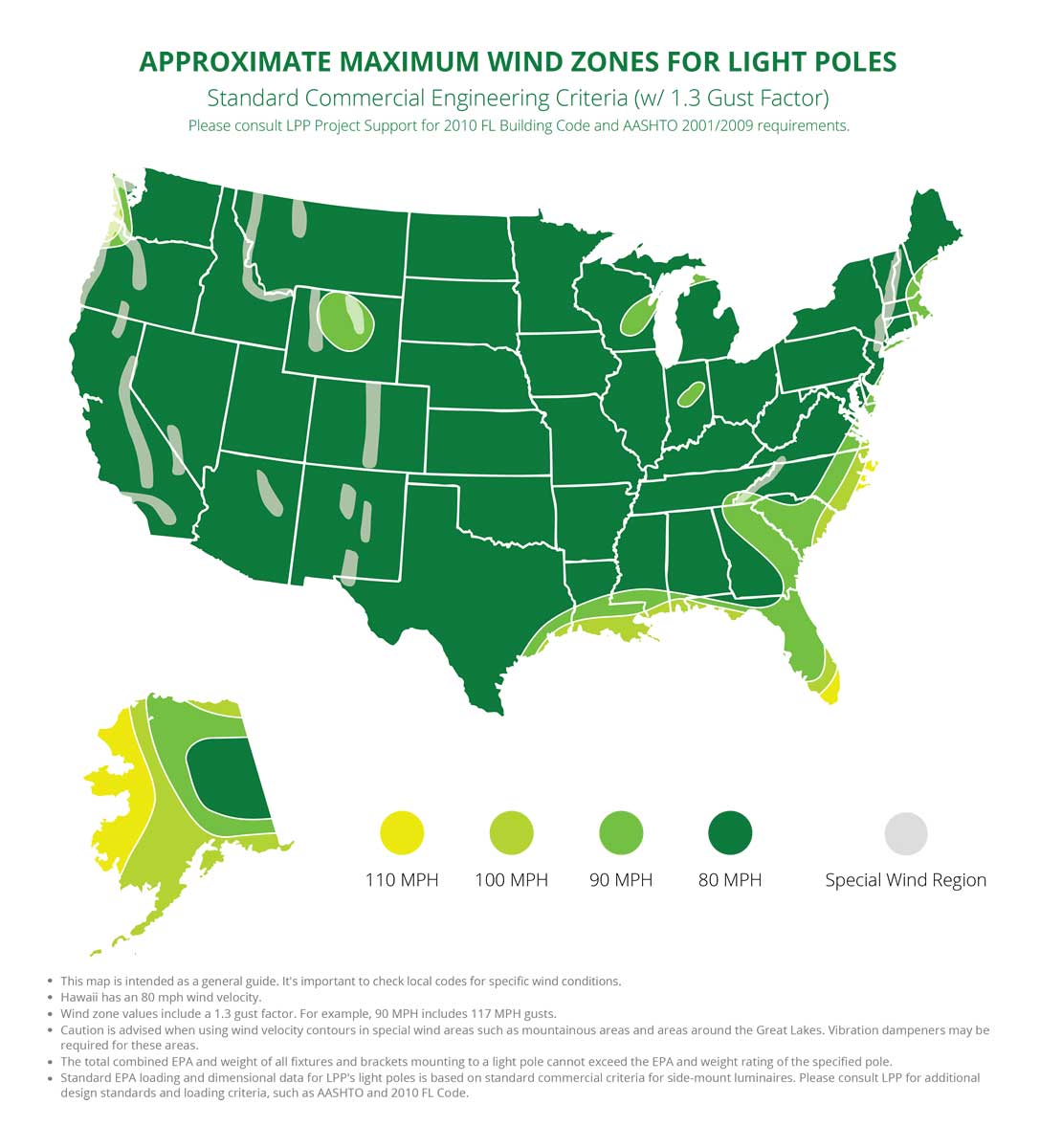

The EPA wind rating of a light fixture refers to the maximum wind speed the fixture can withstand before it is at risk of failure. This failure could be with the luminaire itself, or a failure with the fixture or the hardware connecting it to a light pole.

The EPA wind rating of a light fixture refers to the maximum wind speed the fixture can withstand before it is at risk of failure. This failure could be with the luminaire itself, or a failure with the fixture or the hardware connecting it to a light pole.